Technologies and services

Our nanoforming technologies, formulation and analytical services span the full range of drug development from small-molecule to large-molecule therapeutics. We accelerate your time to clinic while also increasing possibilities and probabilities of success in taking your product to market by developing the optimal nanoformulation.

Small molecules

Our multi-patented Controlled Expansion of Supercritical Solutions (CESS®) technology enables the creation of API nanoparticles directly from solution. The process can be applied to most small molecules, with a high success rate.

Biologics

Our biological nanoforming technology can deliver large-molecule drug particles as small as 50 nm while retaining biological activity. It’s effectiveness has been demonstrated on proteins in the 1-150 kDa range, and it is capable of engineering particle sizes to specific requirements.

Formulation

Our experienced formulation development team designs and develops flexible dosage forms of nanoformed drug substances to meet preclinical and clinical development as well as life-cycle needs. Our dosage forms cover oral, parenteral, ophthalmic and inhaled therapies and more.

GMP Manufacturing

We have GMP manufacturing capabilities for the manufacture of nanoformed clinical-grade API’s (Active Pharmaceutical Ingredients) for our customers and partners.

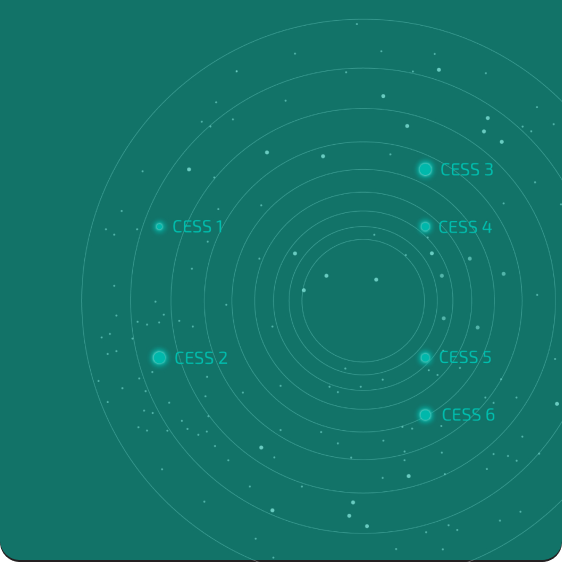

STARMAP®

Our STARMAP® online platform leverages cutting-edge sparse-data AI to pick winners among candidate molecules that are predicted to be best amenable to CESS®-powered nanoforming and that exhibit optimal production characteristics.

Case studies

Our multi-patented Controlled Expansion of Supercritical Solutions (CESS®) technology can enable the creation of uniform small-molecule API nanoparticles as small as 10 nm directly from solution.